Supplied in the following conditions:

| Condition | Yield | Tensile | Elongation |

|---|---|---|---|

| N/mm2 | Re min N/mm2 |

Re min % min |

|

| KM as welded+CR2 | 220 | 310 | 23 |

| Outside Diameter | ||||

|---|---|---|---|---|

| Over | Up to and Including | KM Condition | ||

| mm | mm | mm +/- | ||

| 20 | 0.12 | |||

| 20 | 30 | 0.15 | ||

| 32 | 42.40 | 0.20 | ||

| 44 | 51 | 0.25 | ||

| 55 | 63.50 | 0.30 | ||

| 70 | 76 | 0.35 | ||

| 80 | 90 | 0.40 | ||

| 100 | 101.60 | 0.50 | ||

| n.b The tolerance on outside diameter includes ovality | ||||

The tolerance including eccentricity but excluding the weld, shall be:

a) thickness less 1.5mm: +/- 0.15mm

b) thickness 1.5mm and over: +/- 10% or +/- 0.35mm whichever is the smaller

The maximum concave or convex deflection of a flat side of a square or rectangular section of tube shall not exceed 0.5% of the nominal length of that side.

The maximum height of the internal weld shall not exceed 60% of the specified thickness.

Tubes shall not depart from straightness by more than 1.5 in 1000.

BS EN 10305: 2023 Part 3 E220

| C | Si | Mn | P | S |

|---|---|---|---|---|

| max % | max % | max % | max % | max % |

| 0.14 | 0.35 | 0.70 | 0.025 | 0.025 |

Also Available in BS EN 10305-3: 2023

| O.D (mm) | Wall | 0.71 | 0.81 | 0.91 | 1.00 | 1.22 | 1.50 | 1.63 | 2.00 | 2.03 | 2.50 | 2.64 | 2.95 | 3.25 | 3.50 | 4.06 | 4.88 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| O.D. | – | ||||||||||||||||

| 9.53 | – | x | x | ||||||||||||||

| 10.00 | – | x | x | x | |||||||||||||

| 12.00 | – | x | x | x | |||||||||||||

| 12.70 | – | x | x | x | x | ||||||||||||

| 13.50 | – | x | |||||||||||||||

| 14.00 | – | x | x | ||||||||||||||

| 15.00 | – | x | x | x | |||||||||||||

| 15.88 | – | x | x | x | x | x | x | x | x | ||||||||

| 16.00 | – | x | x | x | x | ||||||||||||

| 17.20 | – | x | |||||||||||||||

| 18.00 | – | x | x | x | x | x | |||||||||||

| 19.05 | – | x | x | x | x | x | x | x | |||||||||

| 20.00 | – | x | x | x | |||||||||||||

| 21.30 | – | x | |||||||||||||||

| 22.00 | – | x | x | ||||||||||||||

| 22.22 | – | x | x | x | x | x | x | x | |||||||||

| 25.00 | – | x | x | x | x | x | x | x | |||||||||

| 25.40 | – | x | x | x | x | x | x | x | x | ||||||||

| 26.98 | – | x | x | ||||||||||||||

| 28.00 | – | x | x | ||||||||||||||

| 28.58 | – | x | x | x | x | x | x | ||||||||||

| 30.00 | – | x | x | ||||||||||||||

| 31.75 | – | x | x | x | x | x | x | x | |||||||||

| 33.70 | – | x | |||||||||||||||

| 34.93 | – | x | x | x | x | x | |||||||||||

| 35.00 | – | x | x | ||||||||||||||

| 38.10 | – | x | x | x | x | x | x | x | |||||||||

| 40.00 | – | x | x | ||||||||||||||

| 41.28 | – | x | x | x | x | ||||||||||||

| 44.45 | – | x | x | x | x | x | x | ||||||||||

| 45.00 | – | x | x | ||||||||||||||

| 47.63 | – | x | x | x | x | x | |||||||||||

| 50.00 | – | x | x | ||||||||||||||

| 50.80 | – | x | x | x | x | x | x | x | |||||||||

| 53.98 | – | x | x | x | |||||||||||||

| 57.15 | – | x | x | x | x | ||||||||||||

| 60.00 | – | x | x | x | |||||||||||||

| 60.33 | – | x | x | x | |||||||||||||

| 63.50 | – | x | x | x | x | x | x | ||||||||||

| 66.68 | – | x | |||||||||||||||

| 69.85 | – | x | x | x | x | ||||||||||||

| 76.10 | – | x | x | x | x | x | x | ||||||||||

| 80.00 | – | x | x | ||||||||||||||

| 88.90 | – | x | x | x | x | ||||||||||||

| 101.60 | – | x | x | x | x | x | x | ||||||||||

| 108.00 | – | x | |||||||||||||||

| 114.30 | – | x | x | x | |||||||||||||

| 127.00 | – | x | x | x | |||||||||||||

| 133.00 | – | x | |||||||||||||||

| 139.70 | – | x | |||||||||||||||

| 152.40 | – | x | x |

Also Available in BS EN 10305-3: 2023

| Wall | 0.91 | 1.00 | 1.22 | 1.50 | 1.63 | 2.00 | 2.03 | 2.34 | 2.50 | 2.64 | 3.00 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20.00 x 10.00 | – | x | x | |||||||||

| 20.00 x 15.00 | – | x | x | x | ||||||||

| 25.00 x 10.00 | – | x | ||||||||||

| 25.00 x 12.00 | – | x | ||||||||||

| 25.00 x 15.00 | – | x | x | x | ||||||||

| 25.00 x 20.00 | – | x | x | x | x | |||||||

| 25.40 x 12.70 | – | x | x | x | ||||||||

| 30.00 x 10.00 | – | x | x | x | ||||||||

| 30.00 x 15.00 | – | x | x | x | ||||||||

| 30.00 x 20.00 | – | x | x | x | x | x | ||||||

| 30.00 x 25.00 | – | x | x | |||||||||

| 31.75 x 15.88 | – | x | x | x | x | |||||||

| 31.75 x 19.05 | – | x | x | x | ||||||||

| 34.93 x 15.88 | – | x | x | x | x | |||||||

| 35.00 x 15.00 | – | x | x | |||||||||

| 35.00 x 16.00 | – | x | x | |||||||||

| 35.00 x 20.00 | – | x | x | |||||||||

| 38.10 x 12.70 | – | x | ||||||||||

| 38.10 x 19.05 | – | x | x | x | x | |||||||

| 38.10 x 25.40 | – | x | x | x | ||||||||

| 40.00 x 10.00 | – | x | ||||||||||

| 40.00 x 15.00 | – | x | x | |||||||||

| 40.00 x 20.00 | – | x | x | x | x | |||||||

| 40.00 x 25.00 | – | x | x | x | ||||||||

| 40.00 x 30.00 | – | x | x | |||||||||

| 45.00 x 20.00 | – | x | x | |||||||||

| 45.00 x 25.00 | – | x | x | x | ||||||||

| 45.00 x 30.00 | – | x | x | |||||||||

| 47.63 x 23.81 | – | x | x | |||||||||

| 50.00 x 10.00 | – | x | ||||||||||

| 50.00 x 15.00 | – | x | ||||||||||

| 50.00 x 20.00 | – | x | x | |||||||||

| 50.00 x 25.00 | – | x | x | x | x | |||||||

| 50.00 x 30.00 | – | x | x | |||||||||

| 50.00 x 34.00 | – | x | ||||||||||

| 50.00 x 40.00 | – | x | x | x | ||||||||

| 50.80 x 25.40 | – | x | x | x | x | x | ||||||

| 50.80 x 38.10 | – | x | x | |||||||||

| 60.00 x 20.00 | – | x | x | x | ||||||||

| 60.00 x 25.00 | – | x | x | |||||||||

| 60.00 x 30.00 | – | x | x | x | ||||||||

| 60.00 x 40.00 | – | x | x | |||||||||

| 63.50 x 25.40 | – | x | x | |||||||||

| 63.50 x 38.10 | – | x | x | x | ||||||||

| 70.00 x 20.00 | – | x | x | |||||||||

| 70.00 x 25.00 | – | x | ||||||||||

| 70.00 x 30.00 | – | x | ||||||||||

| 70.00 x 40.00 | – | x | ||||||||||

| 70.00 x 50.00 | – | x | ||||||||||

| 75.00 x 25.00 | – | x | x | x | ||||||||

| 80.00 x 20.00 | – | x | x | |||||||||

| 80.00 x 30.00 | – | x | x | |||||||||

| 80.00 x 40.00 | – | x | x | |||||||||

| 100.00 x 25.00 | – | x | ||||||||||

| 100.00 x 30.00 | – | x | ||||||||||

| 100.00 x 34.00 | – | x | ||||||||||

| 100.00 x 40.00 | – | x | ||||||||||

| 100.00 x 50.00 | – | x | ||||||||||

| 120.00 x 60.00 | – | x | x |

Also Available in BS EN 10305-3: 2023

| Wall | 0.91 | 1.00 | 1.22 | 1.50 | 1.63 | 2.00 | 2.03 | 2.34 | 2.50 | 2.64 | 3.00 | 3.25 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10.00 x 10.00 | – | x | x | ||||||||||

| 12.00 x 12.00 | – | x | |||||||||||

| 12.70 x 12.70 | – | x | x | x | x | ||||||||

| 15.88 x 15.88 | – | x | x | x | x | x | |||||||

| 16.00 x 16.00 | – | x | x | x | |||||||||

| 18.00 x 18.00 | – | x | |||||||||||

| 19.05 x 19.05 | – | x | x | x | x | x | |||||||

| 20.00 x 20.00 | – | x | x | x | x | ||||||||

| 22.22 x 22.22 | – | x | x | x | x | x | |||||||

| 25.00 x 25.00 | – | x | x | x | x | x | |||||||

| 25.40 x 25.40 | – | x | x | x | x | x | x | x | |||||

| 28.58 x 28.58 | – | x | x | x | x | ||||||||

| 30.00 x 30.00 | – | x | x | x | x | x | |||||||

| 31.75 x 31.75 | – | x | x | x | x | x | |||||||

| 34.93 x 34.93 | – | x | x | x | x | ||||||||

| 35.00 x 35.00 | – | x | x | x | |||||||||

| 38.10 x 38.10 | – | x | x | x | x | x | x | ||||||

| 40.00 x 40.00 | – | x | x | x | x | x | |||||||

| 45.00 x 45.00 | – | x | x | x | |||||||||

| 50.00 x 50.00 | – | x | x | x | x | ||||||||

| 50.80 x 50.80 | – | x | x | x | x | x | |||||||

| 60.00 x 60.00 | – | x | x | x | |||||||||

| 80.00 x 80.00 | – | x | |||||||||||

| 90.00 x 90.00 | – | x | |||||||||||

| 100.00 x 100.00 | – | x |

Also Available in BS EN 10305-3: 2023

| Wall | 1.00 | 1.22 | 1.50 | 1.63 | 2.00 | 2.03 | 2.64 | 2.95 | |

|---|---|---|---|---|---|---|---|---|---|

| 20.00 x 10.00 | – | x | |||||||

| 25.00 x 12.00 | – | x | |||||||

| 30.00 x 15.00 | – | x | x | ||||||

| 30.00 x 16.00 | – | x | |||||||

| 31.75 x 15.88 | – | x | x | x | x | x | |||

| 35.00 x 15.00 | – | x | |||||||

| 35.00 x 20.00 | – | x | x | ||||||

| 38.10 x 25.40 | – | x | x | x | x | ||||

| 40.00 x 20.00 | – | x | x | x | x | ||||

| 41.28 x 22.22 | – | x | x | x | x | ||||

| 41.70 x 22.61 | – | x | x | x | x | ||||

| 44.45 x 19.05 | – | x | |||||||

| 45.00 x 17.00 | – | x | |||||||

| 45.00 x 20.00 | – | x | x | x | x | ||||

| 50.00 x 20.00 | – | x | |||||||

| 50.00 x 25.00 | – | x | x | ||||||

| 60.00 x 20.00 | – | x | |||||||

| 60.00 x 30.00 | – | x | x | ||||||

| 66.68 x 33.34 | – | x | x | ||||||

| 70.00 x 20.00 | – | x | x | x | |||||

| 127.00 x 19.00 | – | x |

| Wall | 1.00 | 1.22 | 1.50 | 1.63 | 2.00 | 2.03 | 2.64 | 2.95 | |

|---|---|---|---|---|---|---|---|---|---|

| 18.72 x 12.62 | – | x | |||||||

| 22.22 x 12.70 | – | x | x | x | x | ||||

| 23.50 x 13.34 | – | x | x | x | x | ||||

| 26.29 x 16.21 | – | x | x | x | x | ||||

| 32.00 x 17.50 | – | x | x | x | x | ||||

| 38.10 x 25.40 | – | x | x | x | x |

Sculptured tube has an embossed outside diameter making it suitable for practical and decorative applications. The embossed surface also increases its strength by up to 50%. Sculptured tube is produced in a series of standard patterns.

Typical Applications

Various sections are available ex stock in a wide range of gauges and sizes.

| Wall | 1.00 | 1.22 | 1.50 | 1.63 | 2.00 | 2.03 | 2.64 | 2.95 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| D’ Section | 40.00 x 20.00 | – | x | x | x | x | ||||

| Trapezoidal | 60.00 x 30.00 | – | x | x | x | x | ||||

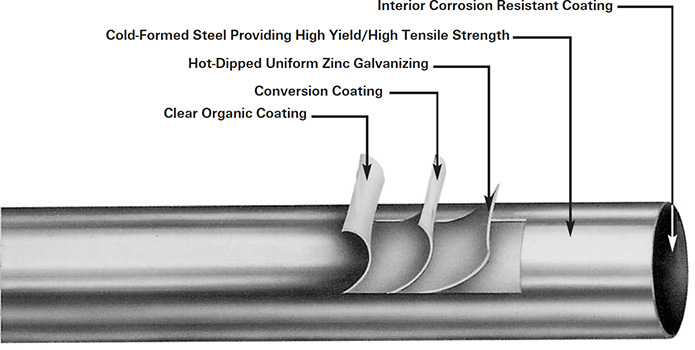

The manufacturing process of coated tube is accomplished automatically ‘in-line,’ quite unlike any other galvanised tube. The consistency of coating is controlled to tolerances unequalled by any other process. The combination of cold forming, heating and rapid cooling inherent in the coating process enhances the mechanical properties of the tube, resulting in higher tensile strength. Its high lustre and smooth coating provides a far superior surface finish to either Pre-galvanised or ‘Hot-Dip’ galvanised along with exceptional corrosion resistance due to the synergy between triple coatings.

When finished products require internal galvanising we can supply tube manufactured from pre-galvanised strip. The weld zone area could be spray weld repaired after the removal of the external fin subject to size feasibility, this requirement must be specified at time of enquiry.

| BS 2982 | EN 10142 |

|---|---|

| Z2 | DX5 1D+Z/+ZF |

| Z28 | S280GD+Z/+ZF |

| Z35 | S350GD+Z/+ZF |

| Wall | 1.00 | 1.22 | 1.50 | 1.63 | 2.00 | 2.03 | 2.64 | 2.95 | |

|---|---|---|---|---|---|---|---|---|---|

| 35.00 x 30.00 | – | x | x | ||||||

| 60.00 x 25.00 | – | x | x | ||||||

| 60.00 x 30.00 | – | x | x |

Discover our extensive range of products that cover a comprehensive specification range to meet your requirements.